Active Harmonic Filtering (AHF) is the power quality solution we recommend for harmonic-rich environments where the power supply is subjected to distortions caused by dynamic, nonlinear loads.

These situations demand real-time solutions to avoid voltage destabilisation, and to maintain network compliance, you need Active Harmonic Filtering.

o VSDs and robotics in manufacturing plants, CT scanners in hospitals, HVAC systems and elevators in shopping centres, sensitive equipment in pharmaceutical cleanrooms, LED lighting and computers in offices – all these are among the many electrical loads that create harmonic distortion. This distortion, if ignored, result in higher energy usage and costs, as well as unnecessary production downtime

What we offer

Our skilled power quality team can survey and analyse, then build and install a bespoke active harmonic filtering solution designed specifically to your unique application and needs.

Contact our expert power quality team today to discuss a solution built around your exact needs.

Merus A2-series filters

Merus A2-series filters are specifically designed for dynamic reactive power compensation and harmonic filtering.

Our skilled power quality team can survey and analyse, then design, build and install a bespoke active harmonic filtering solution designed specifically to your unique application requirements.

We install only the best AHF solutions, using high quality, technically advanced A2-series components from globally renowned Finnish technology specialists Merus Power. They have been a trusted supplier since 2014, and we are proud to be their official UK distributor.

Merus A2-Series AHF filters inject current in real time, ensuring that reactive power is fed efficiently to fast-fluctuating loads, as well as reducing the harmonic voltage distortion by targeting individual harmonic currents so voltage variations and flicker are significantly reduced. All in a neat, compact, space-efficient cubicle.

They combine a state-of-the-art controller built on modern 3-level IGBT-Inverter topology, 7" touch-screen user interface and modular technical design, resulting in a fast, reliable, and compact device that is easy to operate and complies with all standard communication protocols.

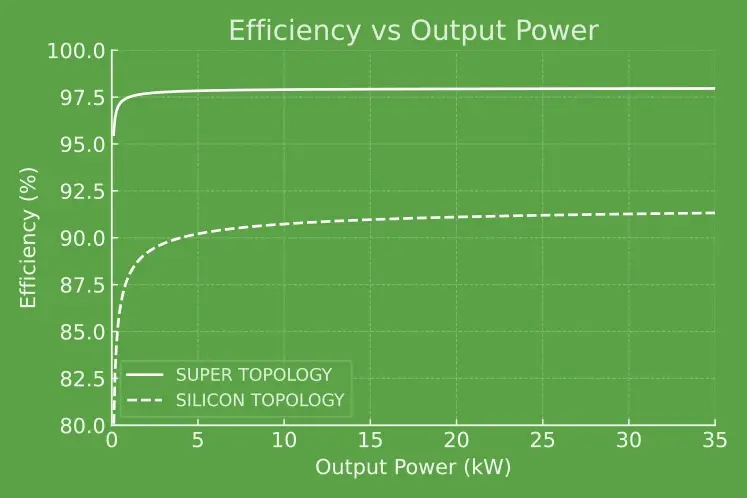

What makes our 3-level topology filters better than those built on conventional 2-level topology?

- Switching frequency and voltage stress are spread across the 2 IGBTs, reducing the stress and extending the lifespan of the power electronics

- Achieves better efficiency and lower losses

- Overall cost of ownership is lower

For more technical detail on the Merus A2-Series filter, download the spec sheet.

The benefits

Our Merus A2-series Active Harmonic Filters are designed for the toughest power quality jobs, delivering immediate benefits from the minute they are installed.

Establishing an optimum level will protect sensitive equipment from voltage fluctuations.

Using advanced 3-level IGBT topology, we deliver high efficiency, minimal losses, low noise (the lowest audible noise among all active filters) and long-lasting electronic performance.

Enjoy energy savings, increased network capacity, reduced maintenance, and extended lifespan of your plant equipment.

Designed to comply with IEEE 519, G5/5, IEC 61000 3-2, 3-4 and similar regulations, you gain peace of mind and avoid costly penalties.

Our smart, touchscreen 'Human Machine Interface' is easy to use - no cryptic codes or complex menus.

Our system lets you connect multiple modules in parallel, easily expanding capacity as demands grow-no technical limits holding you back.

Cost savings can be seen in many ways from day one - lower energy costs, no energy penalties,minimised downtime and equipment issues.

Typical AHF applications

Industries where the power supply is subjected to high harmonic current distortions caused by dynamic, nonlinear loads will see a huge improvement in power quality with Active Harmonic Filtering.

Contact our expert power quality team today to discuss a solution built around your exact needs.

FAQs

An Active Harmonic Filter is a power electronic device that monitors the harmonics in an electrical system and dynamically cancels them out in real time using inverter-based technology.

AHFs are needed when there is a significant level of harmonic distortion in the power system, typically due to non-linear loads like variable speed/frequency drives (VSDs or VFDs), UPS systems, LED lighting, and switch-mode power supplies. In some situations, de-tuned PFC alone is not sufficient to manage harmonics—particularly where sites have sensitive equipment requiring clean power (e.g. medical devices, data centres, specialist manufacturing equipment)

An AHF works by:

- Continuously monitoring the electrical network & analysing the harmonic content.

- Generate counteracting currents (180° out of phase) to cancel harmonics.

- Inject these currents into the system, leaving only the fundamental 50/60 Hz waveform. AHFs can also correct power factor and balance loads in some cases.

- Injecting counter-phase current to neutralize harmonic components—this is done using fast-switching IGBT-based inverters.

Power Factor Correction (PFC) is great for improving displacement power factor caused by inductive loads like motors. However, it doesn’t address harmonics generated by nonlinear equipment such as VFDs, LED lighting, or UPS systems. Active Harmonic Filters (AHFs) not only improve power factor but also eliminate harmful harmonics that PFC capacitors can’t handle – and may even worsen. If your system includes modern electronic loads or suffers from voltage distortion or high THD, an AHF is the better, more comprehensive solution.

Hybrid Power Quality

It could be that your business needs both Active Harmonic Filters and Power Factor Correction to fully optimise your power quality. Our Hybrid Power Quality solution combines both in one system - with greater cost, energy and space savings. Ask about HPQ today.